Up-to-date electronic control for WTC - PWDS - Accumulator Control up to 10 channels

|

Overview:

- IPC-Control based on Windows CE.NET

- Beckhoff TwinCAT control software with hard real time (15μs jitter, time base 1ms)

- Control software, technology software and visualisation on one PC

- Remote diagnostics via lan or modem

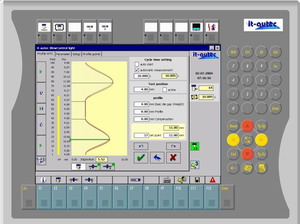

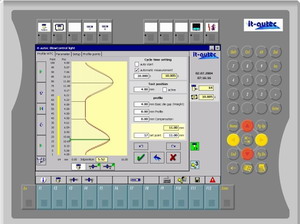

- 12'' TFT operator panel with touch screen

- Data saving by flash memory (compact flash, USB-stick)

- Reversal of language

|

|

System Structure:

- Installation in the wall of the switch board

- PC without fan and hard disk

- Power supply 24V DC

- analog inputs 16Bit (+/- 10V)

- analog outputs 12Bit (+/-10V)

- digitale inputs

- digitale outputs

- Amplifier for the valve (15mA, 20mA, 33mA oder 60mA)

|

|

Operator panel:

- 12'' TFT display

- Resolution 800 x 600 pixel

- Touch screen

- 12 function keys for screen selection

- Numerical keyboard on screen

- 10 PLC-keys with LEDs for activation of special functions

- EtherCAT for the connection to the I/Os

- Installation in the wall of the switch board

|

|

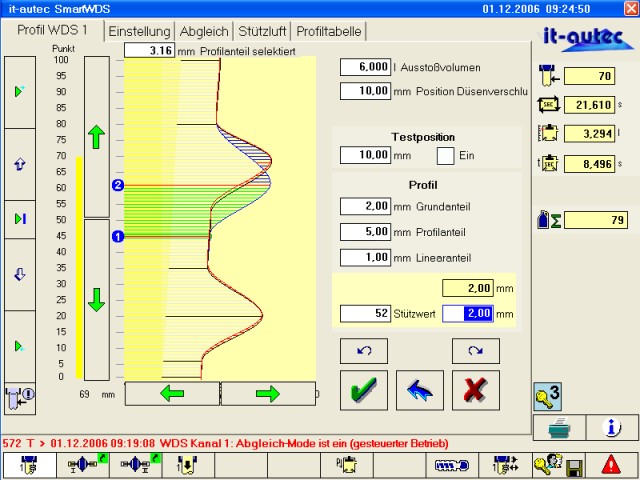

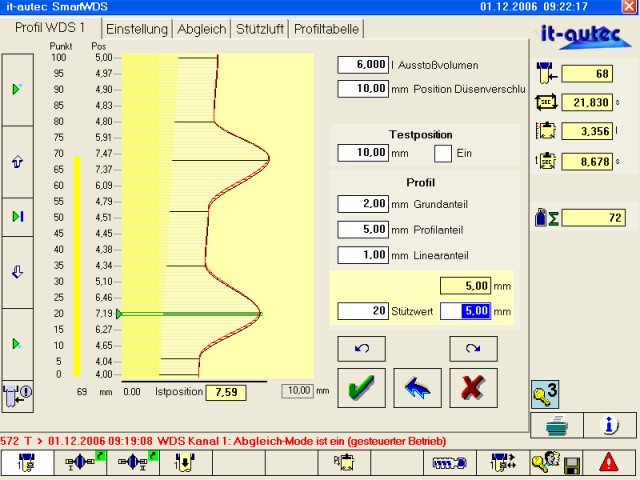

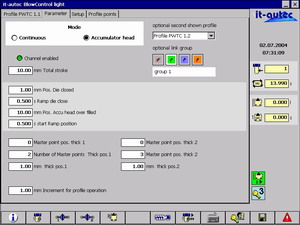

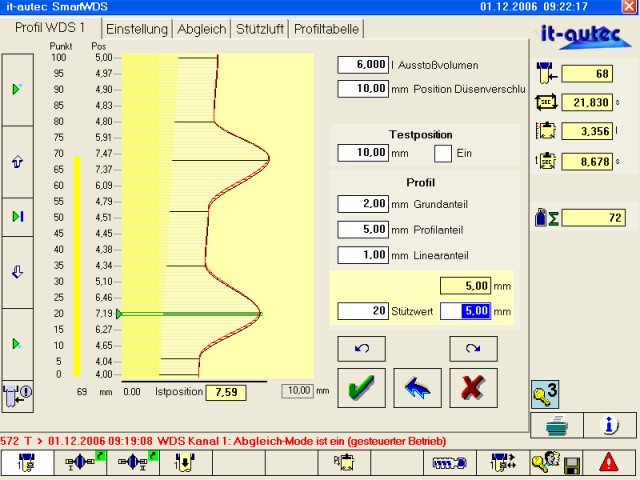

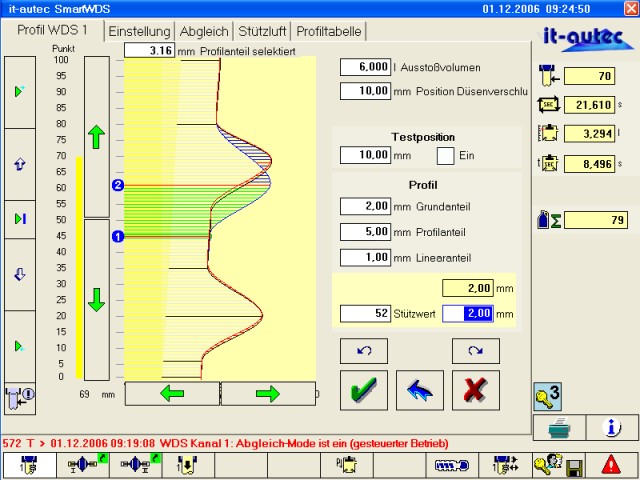

Wall thickness profile:

|

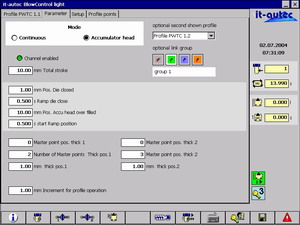

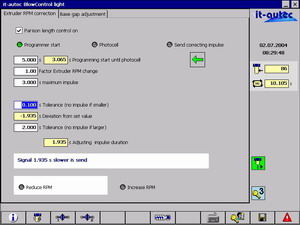

- Continuous or discontinuous extrusion

- 100, 200 or 400 point wall thickness profile

- Up tp 10 channels synchron (wall thickness profile control - partial wall thickness control - multiple extrusion head)

- 1 channel parison ejection (constant or profile)

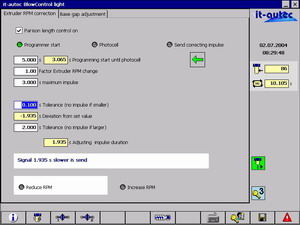

- Correction of parison elongation (linear proportion)

- Cycle time specification manually or automatically

- Parison check marks (max. 2 at the same time) simply by setting of thick or thin places

- Test position

- Control of parison length using a photo cell in case of continuous extrusion

- Filling level control of accumulator head in case of discontinuous extrusion (adjust extruder speed)

- Automatic or maunal calibration of the actual value transmitter (LVDT)

- Profile marker

- All set parameters can be stored or reloaded in an internal memory or an USB-stick

- Reversal of language for the user interface

- User access by PIN-Code

|

|

Information:

SmartWDS is upgradeable up to complete machine control. Here the existent 12'' touch screenm the processor unit and the in- and outputs can be used. Only additional in- and outputs and a software update is required to upgrade follwing available function:

|

- Heating channels (up to 96 channels)

- Closed loop movement control (up to 6 axis)

- Complete machine control

|

|

Note:

Please consider by implement heating and movement control you will achieve a central data maintenance, whereby the heating- and movement-parameters are stored in the same data record.

|

|

|

|

|