Overview:

- IPC-Control based on Windows CE.NET

- PC without fan and harddisk

- Beckhoff TwinCAT control softwrae with hard realtime (15μs jitter, time base 1ms)

- PLC software, technology software and visualisation on one PC

- Remote diagnostics via VPN

- TFT operator panel with touchscreen

- Data saving by flash memory (compactflash, USB-stick) or network

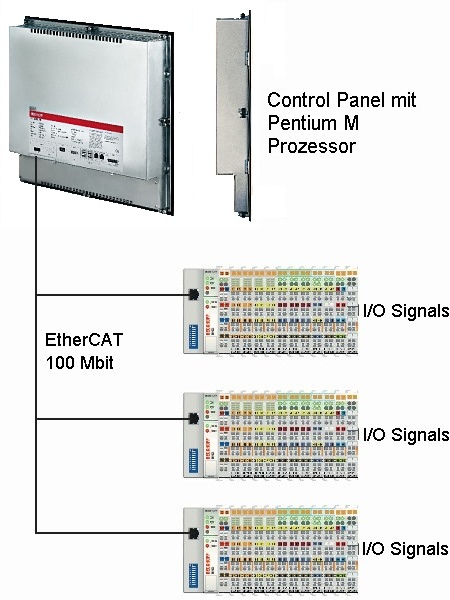

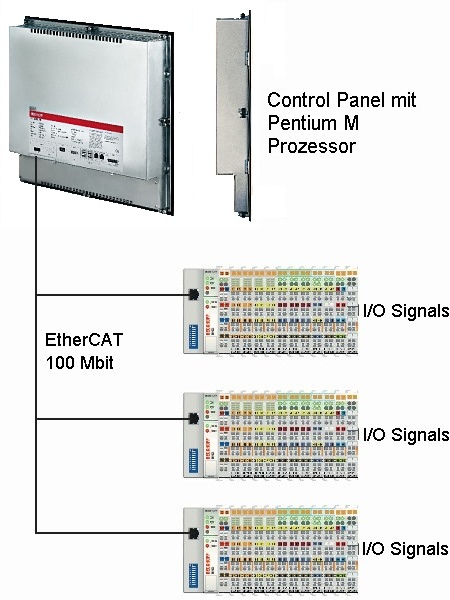

Conception of the control:

- PanelPC

- EtherCAT fieldbus

- Distance for I/O up to 100m (between 2 stations)

- USB- and LAN interfaces

- Optional additional fieldbus (Profibus, CAN, Sercos, ...)

|

|

|

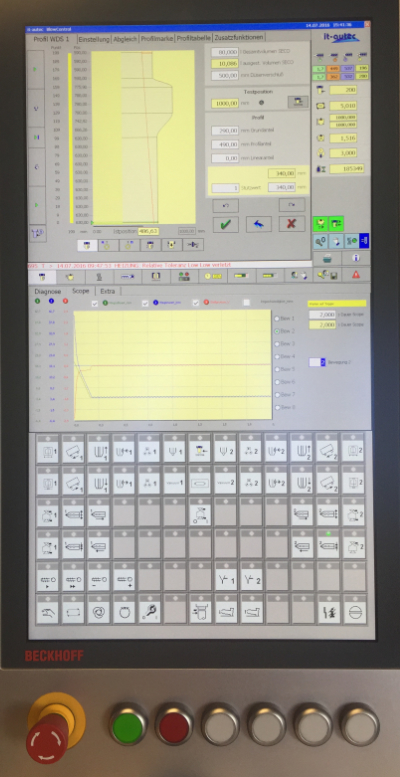

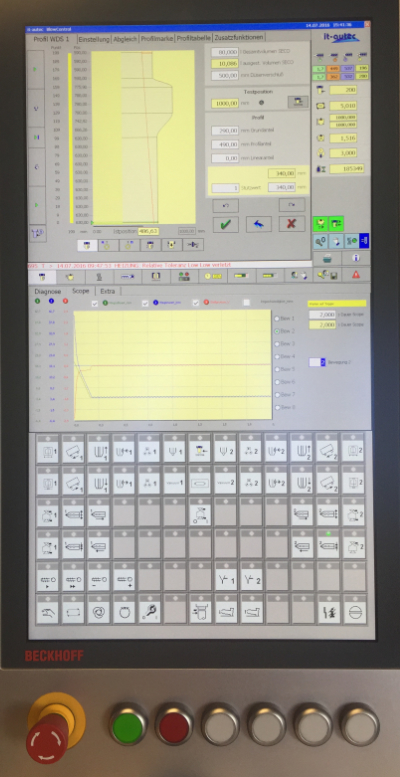

Operator panel:

- Panel PC - Industrial-PC intergated in the panel

- 12'' TFT display

- Touchscreen

- 12 function keys for screen selection

- Numerical keyboard, cursor block

- 10 PLC-keys with LED for activation of special functions

- EtherCAT fieldbus 100MBit

- Ethernet 100/1000 MBit

- Installation in the wall of the switch board or panel version

|

Advantage at a glance:

- Control system for combine PLC-, motion control- and visualisation functions

- Function independent hardware, all software modules are installed in one CPU

- Industrial PC with PLC chracteristics, without fan and rotating memory disk, fast booting, real time clock, exchange of programs by storage cards, remanent memory and operation without UPS

- Efficient CPU; Intel Celeron M, 1 GHZ Taktfrequenz

- Operation system of the latest generation: Microsoft Windows CE.NET

- Ethernet, EtherCAT, COM1 and USB already installed in the basic version

- Support of the most fieldbus systems like Profibus, CANOpen, DeveiceNET, SERCOS and Lightbus

- Ability to fit for WEB-server or FTP-server for internet-/intranet applications

- Via analog modem conected to the serial interface PLC software changes and Remote Desctop (screen 1 to 1 from the remote computer visible) can be done.

- Low heat and low power consumption

- Small measurements of the system require little space within the switch board or terminal box

|

|

Wall thickness (WTC):

|

|

Motion control:

|

|

Temperature summary page:

|

|

Temperature controller:

|

|

Proportional blowing:

|

|

Configurable Customer pages: e.g. Spreading device

|

|

Process data monitoring (PDM):

|

|

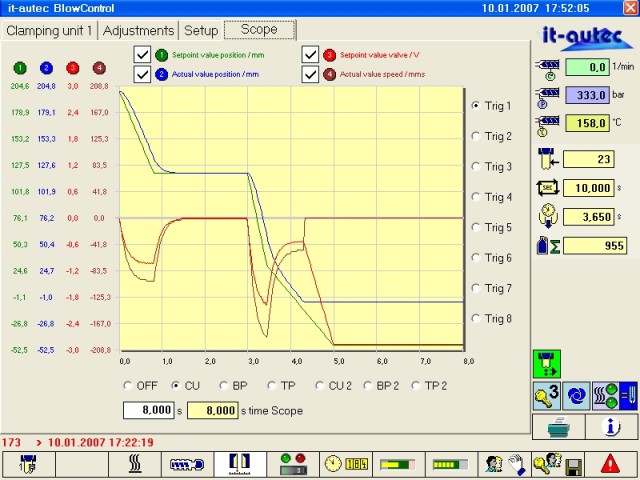

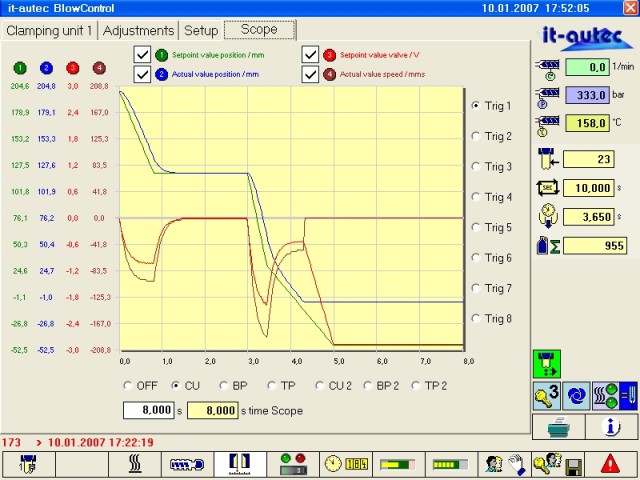

Scope:

|

Function overview:

- Temperature control for extruder and head, 2-and 3 point controller, self optimizing

- Wall thickness control up to 10 channels (selectively 100, 200 or 400 setpoints)

- Accumulator head operation (constant or profiled, 3 heads)

- Extruder speed control, synchronized adjustment when operation more than 1 extruder

- Parison lenght control in case of continuous extrusion

- Filling level control and die adjustment during accumulator head operation

- Distance cams for clamping unit and blowpin

- Closed loop motion control for hydraulic axis

- Blow mould open / close

- Blowpin movement

- Blow mould movement

- Motion control for electrical axis

- Display of melt temperature, melt pressure, extruder speed, extruder torque or current

- Monitoring of process parameters as e.g. melt temperature, melt pressure, Timers, ect.

- Sequence control of the machine - presections, timers and counters are shown on the display

- Display of blowing devolution in a diagram

- Diagnostics, error messages in plain text with timestamp

- Operator protocal: Each change of value by the user is logged in a file (wtih following information: timestamp, user, user-level, old value, new value).

- Process data monitoring: important process data (e.g. cycle time, blowing time, extruder rpm, melt pressure, melt temperature, other temperatures, etc.) are displayed in a chart and logged in a file (text-, XML-File or connection to SQL-server) for each cycle.

- Integrated scope functionality of motion actual- and setpoint- values

- Configurable access levels: The access of each input control (input fileds, preselections. timers. check boxes, buttons, ...) can be changed individual on screen.

- Limit values for numeric input can be changed individual on screen.

- Saving of setting parameters internal, on USB-stick or network. The setting paramaters can be organized in different groups like wallthickness-, temperature or movement values.

- Language reversal for up t 8 languages at the same time. (asia character sets are supported)

- Access control via PIN-code, optional fingerprint. 3 access level, 1 administrator

- Hardcopy function: One or all screen pages can be stored on USB-stick or network.

- Online help: At each page the help button displays the help page for this screen in the browser.

- The complete user manual is deposited in HTML-files on the system.

|

|

|

|

|

|

|

|

|

|

|

|

|