Up-to-date electronic control for WTC - PWDS - Accumulator Control up to 10 channels

|

Overview:

|

|

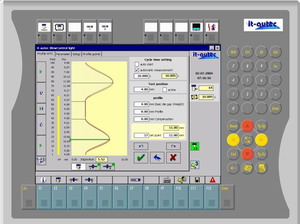

System Structure:

|

|

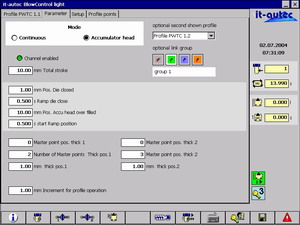

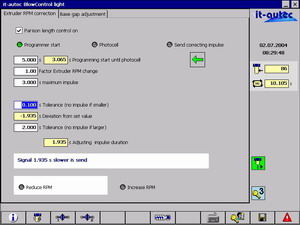

Operator panel:

|

|

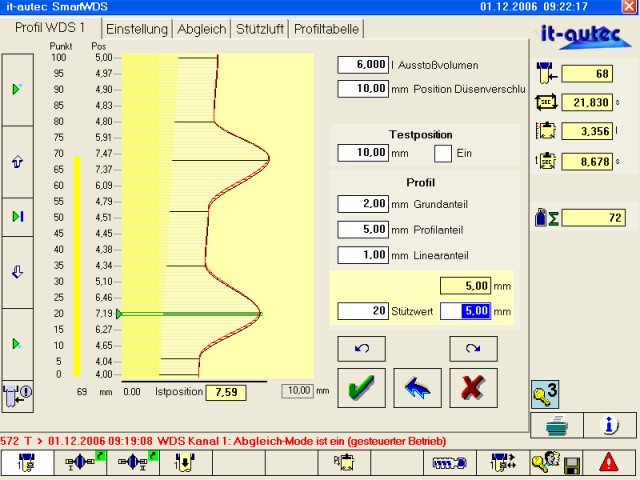

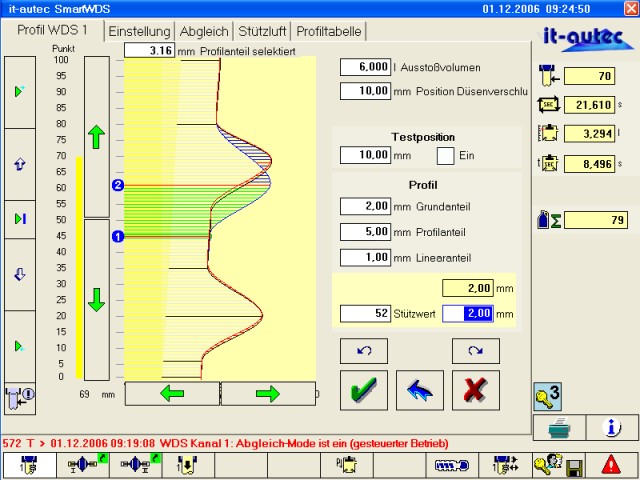

Wall thickness profile:

|

|

|

|

|

Information: SmartWDS is upgradeable up to complete machine control. Here the existent 12'' touch screenm the processor unit and the in- and outputs can be used. Only additional in- and outputs and a software update is required to upgrade follwing available function: |

|

|

|

|

Note: Please consider by implement heating and movement control you will achieve a central data maintenance, whereby the heating- and movement-parameters are stored in the same data record. |

|

|

|

|

|

|